Why settle for convention? Are you ready to experience the next generation of thermal management applications?

Date: 17 July 2025

Time: 14:00pm (UK)

Duration: 30 minutes

Agenda:

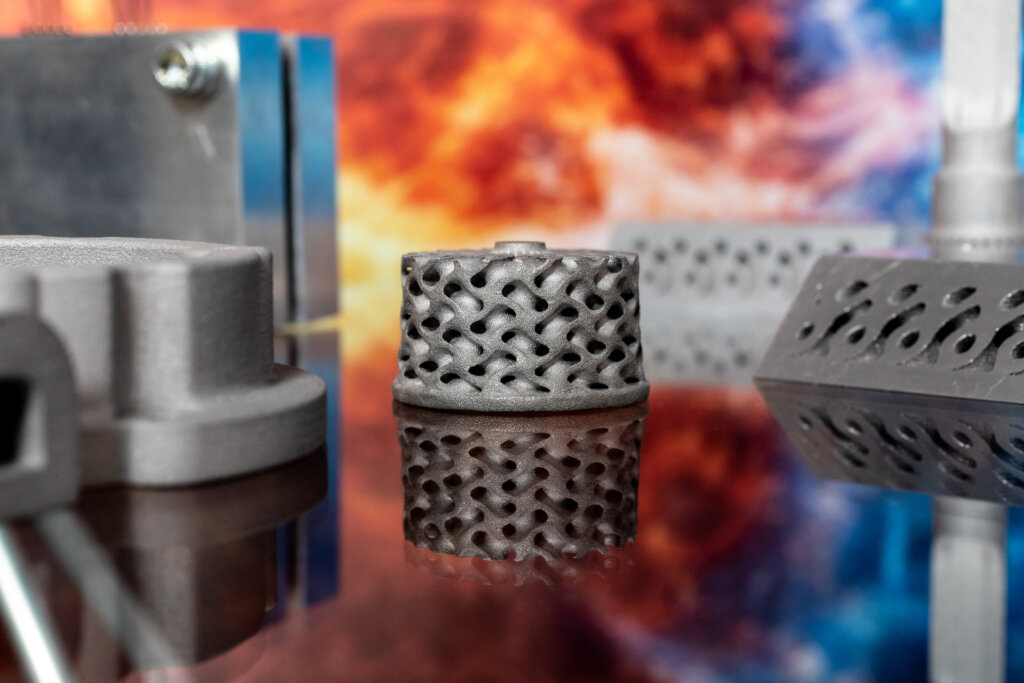

What’s possible when you combine Ricoh’s cutting-edge aluminium binder jetting technology with powerful physics-driven generative design software from ToffeeX?

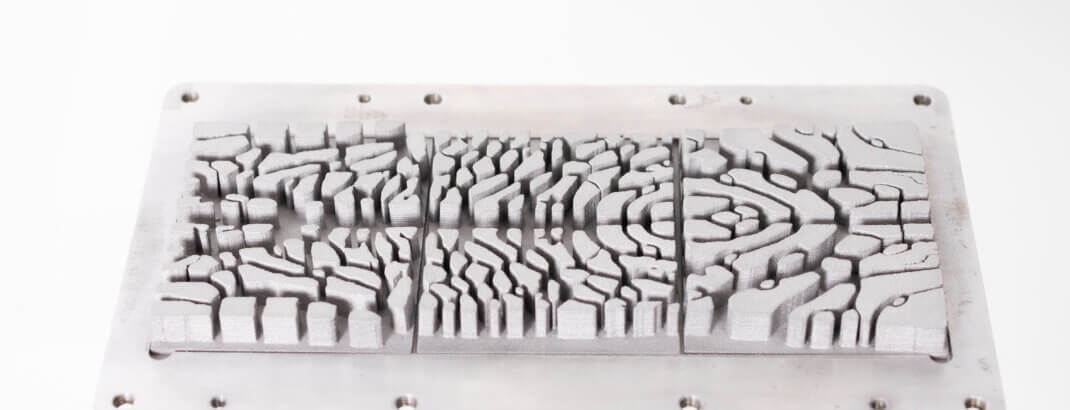

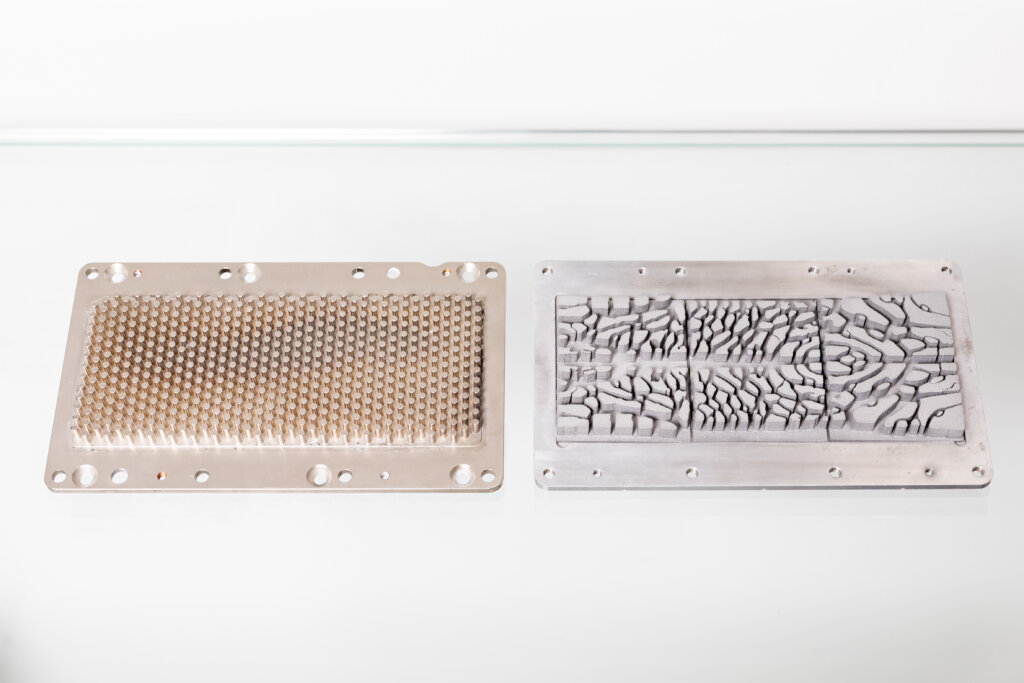

Ricoh 3D and ToffeeX collaborated to design an innovative cold plate for inverters in electric vehicle motor drives, achieving remarkable performance improvements through advanced design fluid-topology optimisation techniques.

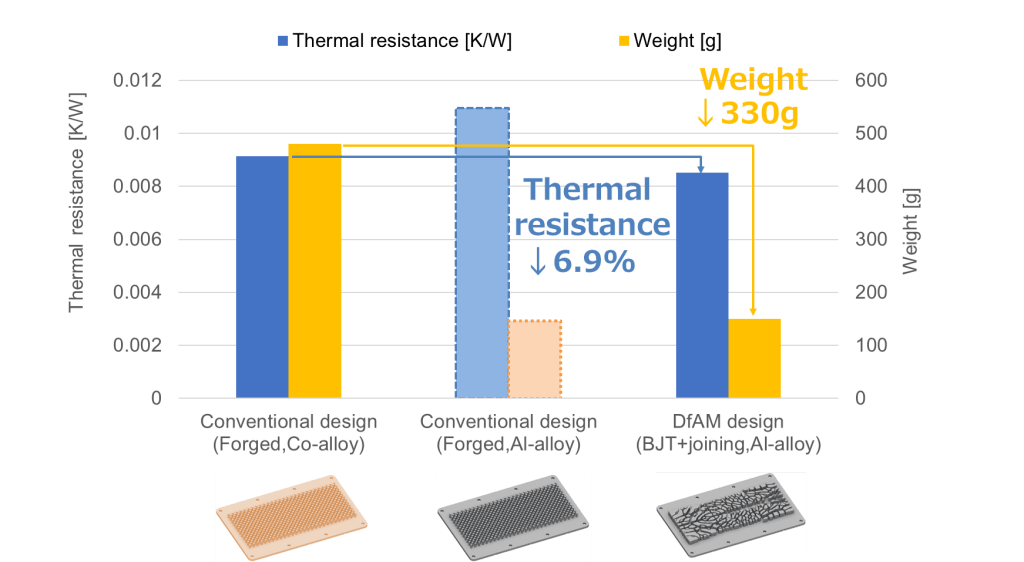

The redesigned cold plate demonstrated exceptional results:

- Enhanced thermal performance with a 6.9% lower thermal resistance

- Improved flow distribution resulting in a 31% reduction in pressure loss

- A significant 68% reduction in overall weight compared to a traditional copper design

Find out from the engineering and design experts how you too can deliver premium thermal performance while maintaining cost-effectiveness, taking products from prototype to production quicker than ever before…

Together, we can reshape the future of thermal management applications.

Format:

- 5 mins – An introduction to Ricoh 3D

- 5 mins – An introduction to ToffeeX

- 10 mins – Case studies

- 5 mins – The future of thermal management and a zero-carbon society

- 5 mins – Q&A

Speakers:

Ricoh 3D:

- Mark Dickin – Head of Additive Manufacturing & Applications

- Enrico Gallino – Senior Engineer & Materials Specialist

- Insei Son – Metal Binder Jetting Engineer

ToffeeX:

- Luca Masi – Vice President of Sales & Business Development

- Thomas Rees – R&D Innovation Manager

Value:

This session is ideal for engineers, designers, and industry professionals in the electronics and IT sector, and automotive, aerospace, and energy sectors, who want to enhance cooling system efficiency through next-generation materials and advanced design automation.

The webinar is also particularly beneficial for businesses who wish to explore co-creation opportunities to further develop Ricoh’s aluminium binder jetting technology and manufacture applications such as inverters, motors, heatsinks, heat exchangers and cooling plates, which will support the realisation of a zero-carbon society.