Selective Laser Sintering

Selective Laser Sintering printing, also referred to as powder bed fusion, is considered the “workhorse” technology of 3D print providers, due to large build volumes and a range of engineering thermoplastics – making it the perfect choice for series manufacture and complex free-form shapes for end-use applications.

How does SLS work?

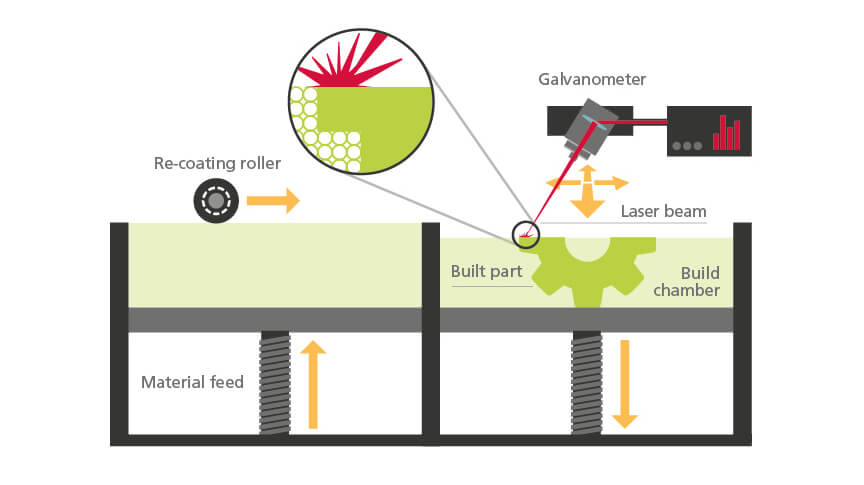

A thin layer of pre-heated polymer powder is layered across a build platform, which is then selectively melted by a laser(s). The build platform then lowers by the defined layer thickness, and another layer of powder is deposited across the bed.

The process is repeated and material is fused together to create a 3D object. As SLS technologies do not require additional support material many parts can be manufactured inside the same build at once, resulting in increased cost-efficiency and minimal waste. The unused powder can be refreshed and reused, making SLS 3D a sustainable production process.

To find out more about SLS technology, contact one of our 3D printing experts here.