CO-AM: B2B like B2C?

What if ordering industrial-grade 3D prints felt as seamless as ordering your favorite gadget online? For Ricoh 3D, this vision is becoming a reality. With a self-managed system that facilitates online ordering and instant quoting to accelerate additive manufacturing (AM), Ricoh 3D enhances the customer experience while giving the technical experts more time to focus on high-value tasks.

Ricoh 3D’s AM Journey

RICOH began its AM journey in 2015. They initially sold print systems before introducing full-service AM solutions in 2019. Now, their offering includes high-quality end-use parts and comprehensive manufacturing solutions — from prototyping to mass production.

According to AM’s increasingly competitive landscape, Ricoh 3D knew they needed to penetrate the market as not just a printer manufacturer, but as a strategic partner. Customers accustomed to traditional manufacturing often have misconceptions about 3D printing, so Ricoh 3D, still today, stresses the necessity of education, knowledge-sharing and co-creation in the industry, demonstrating the true value of AM.

Ricoh 3D x Materialise

To support Ricoh 3D’s growth into contract manufacturing – which Ricoh 3D defines as Managed Print, they sought a solution that offered end-to-end traceability and granular insights into the customer and part journey. The answer: Materialise CO-AM Software Platform. With real-time data CO-AM collects from the shop floor and machine sensors, the Ricoh 3D team uses its technical expertise to optimise all production stages and improve real-time decision-making.

“Our focus has always been on value-added activities,” says Mark Dickin, Head of Additive Manufacturing & Applications at Ricoh 3D. “With CO-AM, we are providing a fully self-supporting platform that allows customers to manage their own orders effortlessly while giving us the space to drive further innovation in material, technology, and application development, alongside our partners.”

A Good First Impression — Every Impression

Ricoh 3D prides itself on customer-centricity and personalised service. As part of its Kaizen (continuous improvement) mission, customer feedback shapes the company’s ways of working. Based on thorough data analytics from scroll-through rates, clicks, heatmaps, and surveys, Ricoh 3D identified online ordering as the next area for improvement.

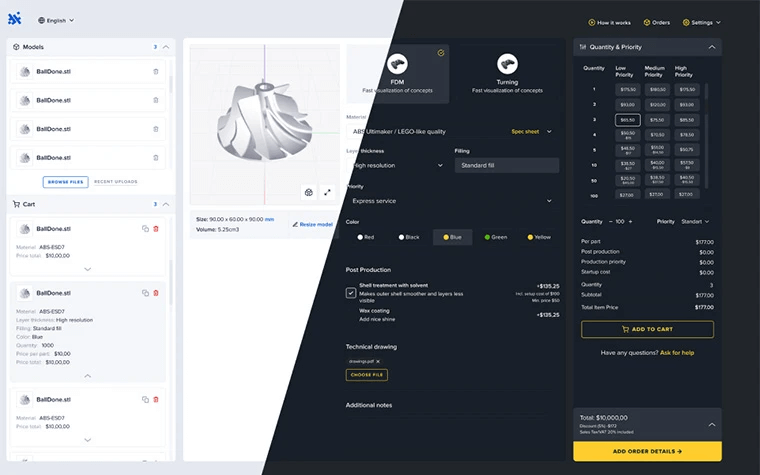

CO-AM plays a pivotal role here, especially with its quoting metrics, which allowed the team to modernise its pricing model. Now, Ricoh 3D offers a bulk pricing tool directly on the customers’ ordering interface.

According to Scott Robinson, Customer Success Manager at DigiFabster: “CO-AM is an open solution, and through its integration with DigiFabster, we can offer our customers an elegant ordering platform. It’s a familiar experience for people accustomed to B2C purchases, but it’s tailored to appeal to a B2B audience.”

The tool not only provides the customer with the price point; it also offers clarity on product viability. Customers can access technicalities of applications, technologies, and materials.

Beyond instant quoting, the software also immediately sends the job to production. In that sense, it mirrors the instant e-commerce transactions everyone expects in today’s fast-paced society.

Another advantage? It allows the experts to concentrate on tasks that make the most impact on their customers, such as advancing R&D and refining ‘beyond print’ initiatives like their unique aluminium binder jetting technology.

Stronger Together

CO-AM reinforces Ricoh 3D’s commitment to quality, and the collaboration between Materialise and Ricoh 3D goes beyond software developer and customer.

“Materialise has been an exceptional partner throughout this journey,” says Mark Dickin. “They have gone beyond offering an ‘out-of-the-box’ solution, working closely with us to customise CO-AM to our specific needs. Their dedicated team, including site visits from Belgium to our UK factory, has ensured a smooth transition, making the process both effective and enjoyable, providing a sense of Fulfilment through Work.

“We had a small window for the development and migration, but it was well-managed. The Materialise team was equally driven to accomplish the task.”

Moving forward, CO-AM will be the backbone of Ricoh 3D’s business operations, used by every team member across commercial, production, and web departments.

This lean operation will help the team expand its customer base in all industries, particularly in the medical, industrial, and automotive segments. CO-AM’s traceability ensures continued compliance with Ricoh 3D’s quality management standards, including ISO 9001 and ISO 13485 certifications.

“With CO-AM, we are not only optimising our own operations but also setting the stage for broader industry advancements,” says Richard Minifie, Senior Engineer and Project Lead. “The co-creation with Materialise is a testament to our vision for the future of AM: smarter, more efficient, and fully integrated manufacturing solutions.”